Description

Basis for assessment EC 3, working loads for Supports in delivery status

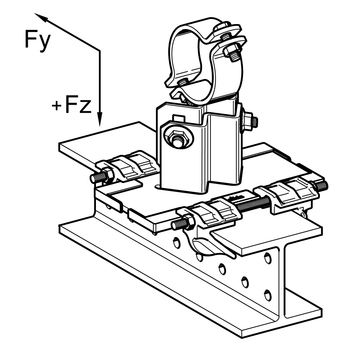

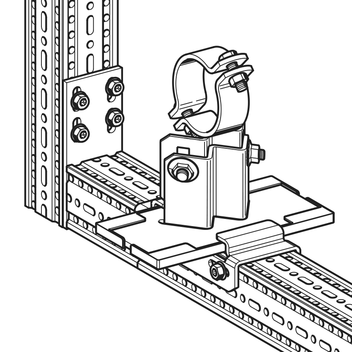

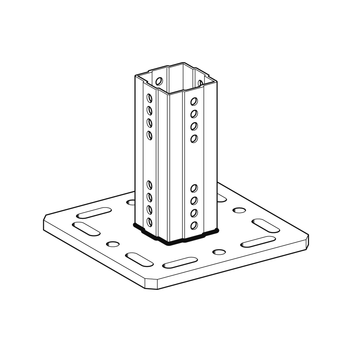

Sliding Support LA – HV + Guiding Set FS resp. Fixed Point Set XS

Sliding Support LA – HV + Guiding Bracket FW F 80 resp. Fixed Point Bracket XW F 80

| Height | DN | Fx * [kN] X-Supports only |

Fy [kN] |

+ Fz [kN] |

– Fz FS 80/120 [kN] |

– Fz FW F 80 [kN] |

– Fz XS 80/120 [kN] |

– Fz XW F 80 [kN] |

|

|---|---|---|---|---|---|---|---|---|---|

| 90 | ≤ 25 | 9.1 | 5.2 | 15.4 | 14 | 6.1 | 15.4 | 15.4 | |

| 90 | 32 | 8.8 | 4.9 | 15.4 | 14 | 6.1 | 15.4 | 15.4 | |

| 90 | 40 | 8.6 | 4.8 | 15.4 | 14 | 6.1 | 15.4 | 15.4 | |

| 90 | 50 | 8.2 | 4.4 | 15.4 | 14 | 6.1 | 15.4 | 15.4 | |

| 90 | 65 | 7.7 | 3.9 | 15.4 | 14 | 6.1 | 15.4 | 15.4 | |

| 90 | 80 | 7.3 | 3.6 | 15.4 | 14 | 6.1 | 15.4 | 15.4 | |

| 90 | 100 | 6.5 | 2.8 | 15.4 | 14 | 6.1 | 15.4 | 15.4 | |

| 90 | 125 | 5.7 | 2.1 | 15.4 | 14 | 6.1 | 15.4 | 15.4 | |

| 90 | 150 | 4.7 | 1.3 | 15.4 | 14 | 6.1 | 15.4 | 15.4 | |

| 150 | ≤ 25 | 8.0 | 4.2 | 15.4 | 14 | 6.1 | 15.4 | 15.4 | |

| 150 | 32 | 7.9 | 3.9 | 15.4 | 14 | 6.1 | 15.4 | 15.4 | |

| 150 | 40 | 7.8 | 3.9 | 15.4 | 14 | 6.1 | 15.4 | 15.4 | |

| 150 | 50 | 7.6 | 3.6 | 15.4 | 14 | 6.1 | 15.4 | 15.4 | |

| 150 | 65 | 7.4 | 3.2 | 15.4 | 14 | 6.1 | 15.4 | 15.4 | |

| 150 | 80 | 7.2 | 3.0 | 15.4 | 14 | 6.1 | 15.4 | 15.4 | |

| 150 | 100 | 6.9 | 2.5 | 15.4 | 14 | 6.1 | 15.4 | 15.4 | |

| 150 | 125 | 6.5 | 2.0 | 15.4 | 14 | 6.1 | 15.4 | 15.4 | |

| 150 | 150 | 6.1 | 1.4 | 15.4 | 14 | 6.1 | 15.4 | 15.4 | |

| 200 | ≤ 25 | 6.3 | 3.6 | 15.4 | 14 | 6.1 | 15.4 | 15.4 | |

| 200 | 32 | 6.2 | 3.5 | 15.4 | 14 | 6.1 | 15.4 | 15.4 | |

| 200 | 40 | 6.2 | 3.4 | 15.4 | 14 | 6.1 | 15.4 | 15.4 | |

| 200 | 50 | 6.0 | 3.2 | 15.4 | 14 | 6.1 | 15.4 | 15.4 | |

| 200 | 65 | 5.9 | 3.0 | 15.4 | 14 | 6.1 | 15.4 | 15.4 | |

| 200 | 80 | 5.7 | 2.8 | 15.4 | 14 | 6.1 | 15.4 | 15.4 | |

| 200 | 100 | 5.5 | 2.4 | 15.4 | 14 | 6.1 | 15.4 | 15.4 | |

| 200 | 125 | 5.2 | 2.0 | 15.4 | 14 | 6.1 | 15.4 | 15.4 | |

| 200 | 150 | 4.9 | 1.6 | 15.4 | 14 | 6.1 | 15.4 | 15.4 |

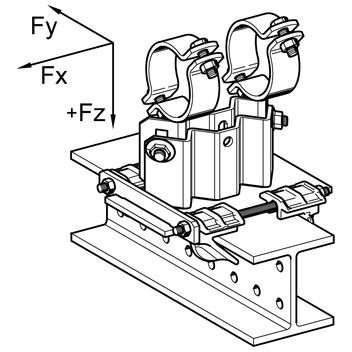

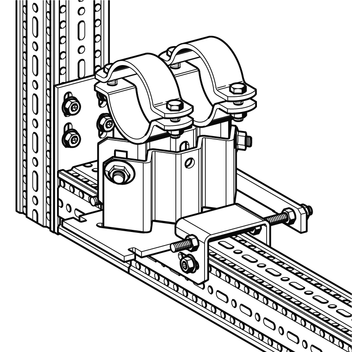

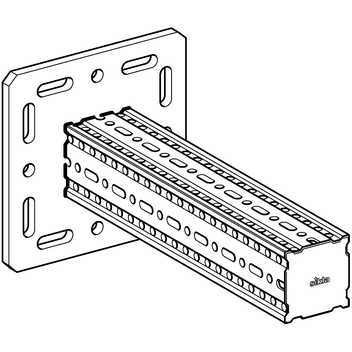

Sliding Support LC – HV + Guiding Set FS resp. Fixed Point Set XS

Sliding Support LC – HV + Guiding Bracket FW F 80 resp. Fixed Point Bracket XW F 80

| Height | DN | Fx * [kN] X-Supports only |

Fy [kN] |

+ Fz [kN] |

– Fz FS 80/120 [kN] |

– Fz FW F 80 [kN] |

– Fz XS 80/120 [kN] |

– Fz XW F 80 [kN] |

|

|---|---|---|---|---|---|---|---|---|---|

| 90 | ≤ 25 | 14.3 | 6.3 | 17.0 | 14 | 6.1 | 17 | 17 | |

| 90 | 32 | 14.1 | 6.2 | 17.0 | 14 | 6.1 | 17 | 17 | |

| 90 | 40 | 14.0 | 6.1 | 17.0 | 14 | 6.1 | 17 | 17 | |

| 90 | 50 | 13.9 | 5.9 | 17.0 | 14 | 6.1 | 17 | 17 | |

| 90 | 65 | 13.6 | 5.6 | 17.0 | 14 | 6.1 | 17 | 17 | |

| 90 | 80 | 13.5 | 5.4 | 17.0 | 14 | 6.1 | 17 | 17 | |

| 90 | 100 | 13.1 | 5.0 | 17.0 | 14 | 6.1 | 17 | 17 | |

| 90 | 125 | 12.7 | 4.5 | 17.0 | 14 | 6.1 | 17 | 17 | |

| 90 | 150 | 12.3 | 4.0 | 17.0 | 14 | 6.1 | 17 | 17 | |

| 90 | 200 | 11.6 | 3.2 | 17.0 | 14 | 6.1 | 17 | 17 | |

| 90 | 250 | 10.8 | 2.3 | 17.0 | 14 | 6.1 | 17 | 17 | |

| 90 | 300 | 10.1 | 1.5 | 17.0 | 14 | 6.1 | 17 | 17 | |

| 150 | ≤ 25 | 8.5 | 4.9 | 17.0 | 14 | 6.1 | 17 | 17 | |

| 150 | 32 | 8.5 | 4.8 | 17.0 | 14 | 6.1 | 17 | 17 | |

| 150 | 40 | 8.5 | 4.7 | 17.0 | 14 | 6.1 | 17 | 17 | |

| 150 | 50 | 8.4 | 4.6 | 17.0 | 14 | 6.1 | 17 | 17 | |

| 150 | 65 | 8.4 | 4.4 | 17.0 | 14 | 6.1 | 17 | 17 | |

| 150 | 80 | 8.4 | 4.3 | 17.0 | 14 | 6.1 | 17 | 17 | |

| 150 | 100 | 8.3 | 4.0 | 17.0 | 14 | 6.1 | 17 | 17 | |

| 150 | 125 | 8.3 | 3.7 | 17.0 | 14 | 6.1 | 17 | 17 | |

| 150 | 150 | 8.2 | 3.3 | 17.0 | 14 | 6.1 | 17 | 17 | |

| 150 | 200 | 8.1 | 2.7 | 17.0 | 14 | 6.1 | 17 | 17 | |

| 150 | 250 | 8.0 | 2.1 | 17.0 | 14 | 6.1 | 17 | 17 | |

| 150 | 300 | 7.9 | 1.5 | 17.0 | 14 | 6.1 | 17 | 17 | |

| 200 | ≤ 25 | 7.3 | 5.3 | 17.0 | 14 | 6.1 | 17 | 17 | |

| 200 | 32 | 7.2 | 5.2 | 17.0 | 14 | 6.1 | 17 | 17 | |

| 200 | 40 | 7.2 | 5.1 | 17.0 | 14 | 6.1 | 17 | 17 | |

| 200 | 50 | 7.1 | 4.9 | 17.0 | 14 | 6.1 | 17 | 17 | |

| 200 | 65 | 7.0 | 4.7 | 17.0 | 14 | 6.1 | 17 | 17 | |

| 200 | 80 | 6.9 | 4.6 | 17.0 | 14 | 6.1 | 17 | 17 | |

| 200 | 100 | 6.7 | 4.3 | 17.0 | 14 | 6.1 | 17 | 17 | |

| 200 | 125 | 6.5 | 4.0 | 17.0 | 14 | 6.1 | 17 | 17 | |

| 200 | 150 | 6.3 | 3.6 | 17.0 | 14 | 6.1 | 17 | 17 | |

| 200 | 200 | 5.9 | 3.0 | 17.0 | 14 | 6.1 | 17 | 17 | |

| 200 | 250 | 5.5 | 2.3 | 17.0 | 14 | 6.1 | 17 | 17 | |

| 200 | 300 | 5.1 | 1.7 | 17.0 | 14 | 6.1 | 17 | 17 |

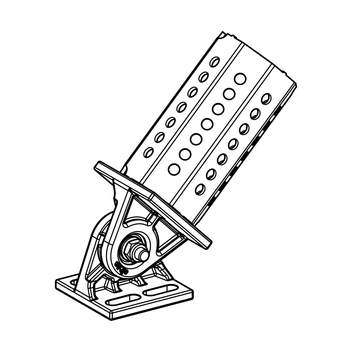

Sliding Support LD – HV + 2 x Guiding Set FS resp. 2 x Fixed Point Sets XS

Sliding Support LD – HV + 2 x Guiding Bracket FW F 80 resp. 2 x Fixed Point Bracket XW F 80

| Height | DN | Fx * [kN] X-Supports only |

Fy [kN] |

+ Fz [kN] |

– Fz FS 80/120 [kN] |

– Fz FW F 80 [kN] |

– Fz XS 80/120 [kN] |

– Fz XW F 80 [kN] |

|

|---|---|---|---|---|---|---|---|---|---|

| 90 | ≤ 350 | 25.0 | 13.1 | 32.8 | 28 | 12.2 | 32.8 | 32.8 | |

| 90 | 400 | 22.5 | 11.9 | 32.8 | 28 | 12.2 | 32.8 | 32.8 | |

| 90 | 500 | 20.8 | 9.4 | 32.8 | 28 | 12.2 | 32.8 | 32.8 | |

| 90 | 600 | 10.3 | 7.2 | 32.8 | 28 | 12.2 | 32.8 | 32.8 | |

| 150 | ≤ 350 | 25.0 | 12.9 | 32.8 | 28 | 12.2 | 32.8 | 32.8 | |

| 150 | 400 | 22.5 | 11.5 | 32.8 | 28 | 12.2 | 32.8 | 32.8 | |

| 150 | 500 | 17.3 | 8.8 | 32.8 | 28 | 12.2 | 32.8 | 32.8 | |

| 150 | 600 | 8.7 | 6.3 | 32.8 | 28 | 12.2 | 32.8 | 32.8 | |

| 200 | ≤ 350 | 25.0 | 11.3 | 32.8 | 28 | 12.2 | 32.8 | 32.8 | |

| 200 | 400 | 20.5 | 10.2 | 32.8 | 28 | 12.2 | 32.8 | 32.8 | |

| 200 | 500 | 15.7 | 8.1 | 32.8 | 28 | 12.2 | 32.8 | 32.8 | |

| 200 | 600 | 7.5 | 6.1 | 32.8 | 28 | 12.2 | 32.8 | 32.8 |

* Axial fixed point forces can only be attained by the professional use of anti-slip protections (e.g. cleats, stoppers). Those have to be planned during the design of the piping and are on the responsibilty of the piping manufacturer.

Further statical product datas are available on request.