Expansion Joints

An expansion joint or movement joint is an assembly designed to hold parts together while safely absorbing temperature-induced expansion and contraction of materials, vibration, or to movement due to ground settlement or seismic activity.

Building faces, concrete slabs, and pipelines expand and contract due to warming and cooling from seasonal variation or other heat sources. Before expansion joint gaps were built into these structures they would crack under the stress induced.

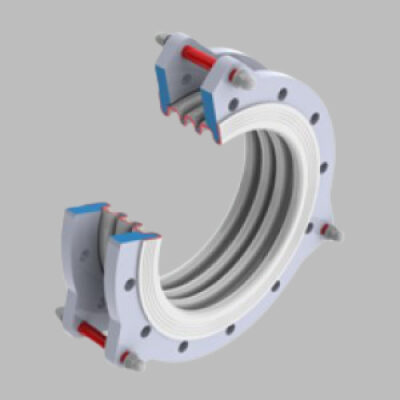

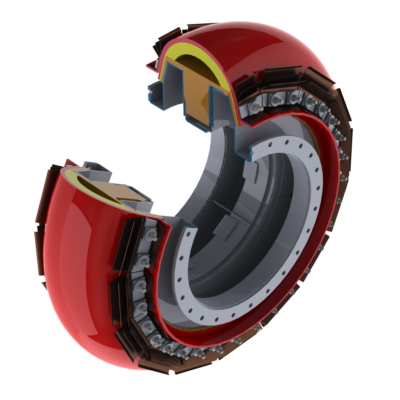

In industrial piping systems, expansion joints are often included to accommodate movement due to thermal and mechanical changes in the system. When processes require large changes in temperature, metal components change size. Expansion joints with metal bellows are designed to accommodate certain movements while minimizing the transfer of forces to sensitive components in the system.

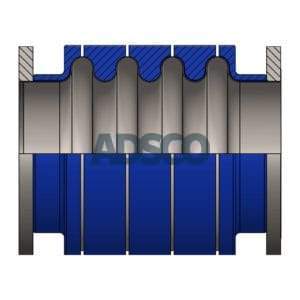

Pipe expansion joints are necessary in systems that convey high temperature substances such as steam or exhaust gases, or to absorb movement and vibration. Expansion joints include bellows of metal, plastic, fabric, or an elastomer such as rubber. A bellows is made up of a series of convolutions, with the shape of the convolution designed to withstand the internal pressures of the pipe, but flexible enough to accept axial, lateral, and angular deflections.

CTS Industries proudly supplies ADSCO, DEKOMTE, and General Rubber expansion joints.

Expansion joints are also designed for other criteria, such as noise absorption, anti-vibration, earthquake movement, and building settlement. Pipe expansion joints are also known as “compensators” as they compensate for the thermal movement.

Showing 1–9 of 10 results