Description

LISEGA Benefits:

• Maintaining a minimum rolling resistance (max. 4%)

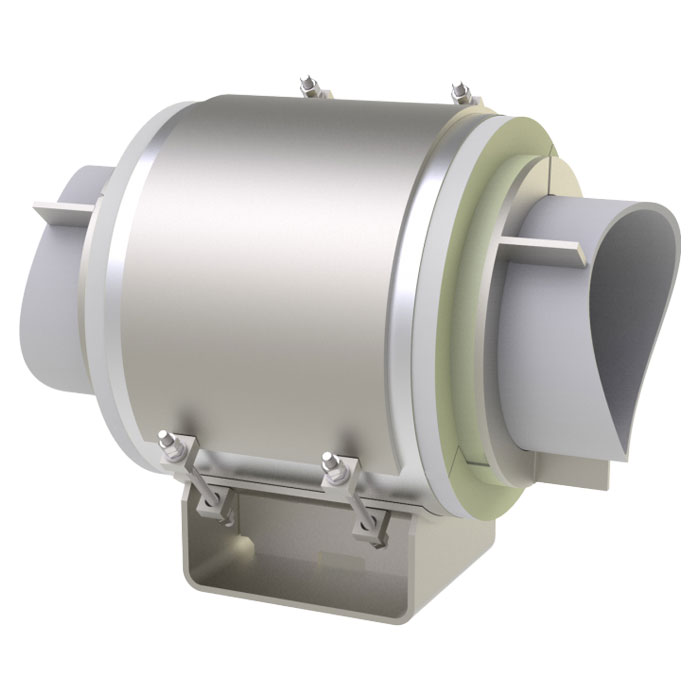

• Compensation of realistic transverse loads with double cone and double cylindrical roller bearings (35% of the support strength)

• In double cylindrical roller bearings, the entire vertical load can be accommodated by a single roll

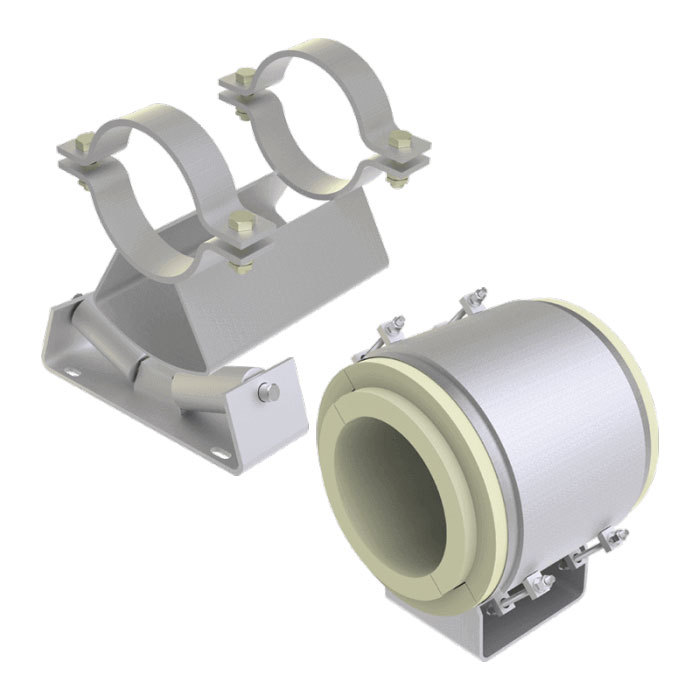

• Compensation of transverse displacements is an option with sideways sliding designs

• Simple and safe design of lift-off restraints

• Pipe saddles allow for convenient load transfer into the tube wall

• Pipe saddle design minimizes heat transmission

• Hot-dip galvanized corrosion protection in all roller bearings

• Maintenance-free operation

• Roller axle made of stainless steel

• Teflon-bronze composite bushings

• Wide range of support diameters (OD 60 mm / 2.36 in – OD 1,350 mm / 53.15 in)

• High load capacity (max. support load 120 kN / 26,977.1 lbf)

• Low installation heights (see selection table for installation dimensions)

• Designed according to recognized international technical regulations and standards.