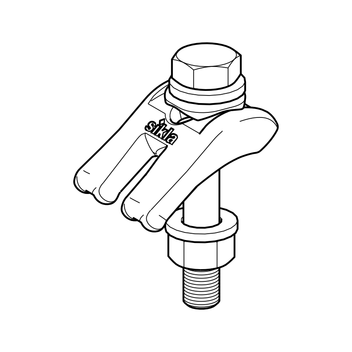

Description

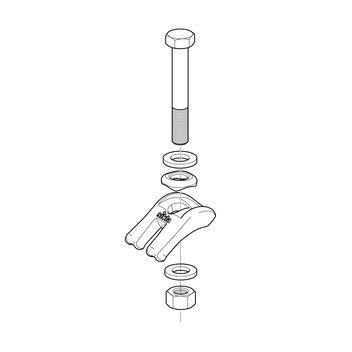

Scope of delivery

| Type | Beam Clip [Quantity] |

Support plate [Quantity] |

HR trimming * [Quantity] |

|---|---|---|---|

| M12 S | 4 x M12 | 4 x M12 | 4 x M12 x 80 |

| M16 S | 4 x M16 | 4 x M16 | 4 x M16 x 100 |

| M12 S2 | 2 x M12 | 2 x M12 | 2 x M12 x 80 |

* HR trimming according EN 14399-3 consisting of: Hexagon bolt M12 or M16, 2 washers, 1 hexagon nut

Installation

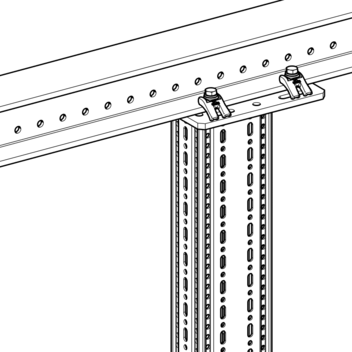

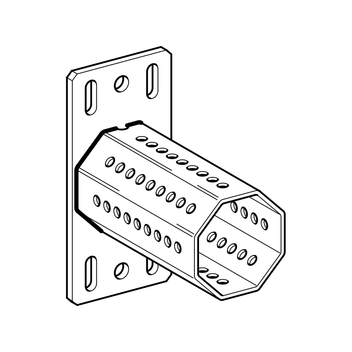

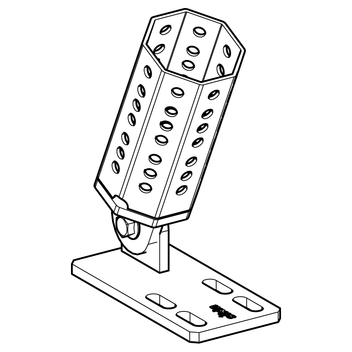

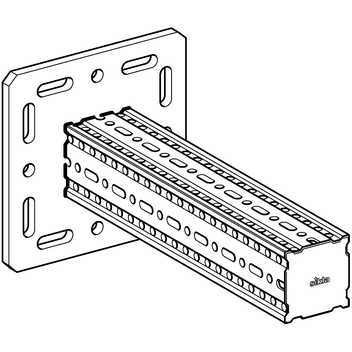

| 1. | Position Beam Clip with the split end on beam section. |

| 2. | Install support plate and HR trimming and tighten accordingly. |

The support plate secures a rectangular assembly of the bolt and prevents its shifting or bending stress. In conjunction with the HR trimming a continuous and predictable preload force is guaranteed.

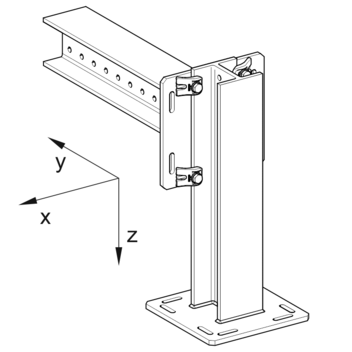

Technical Data

| Type | Size range [mm] |

Tightening torque MA [Nm] |

Fy permitted per Beam Clip [kN] |

Shear force load capacity Fz per set = 4 Beam Clips [kN] |

|---|---|---|---|---|

| M12 S | 1 – 30 | 85 | 26,3 | 12,0 * |

| M16 S | 4 – 40 | 150 | 32,0 | 13,6 * |

* The specified data relate to the worst case with flange thicknesses 30 mnm (M12) or 40 mm (M16) as well as a coefficient of adhesion µadhesion = 0,20.

A possibly operating tensile force Fy isn’t included.

| Material: | Steel, HCP |